We’re proud of what we make

Here’s How We Make It

TREES AND THE

MAPLE SEASON

Maple season in Vermont begins in February and ends in April. In the spring as winter temps rise above freezing, sap begins to flow. Maple trees are special because of the relatively high sugar content of their sap. Maple syrup can be made from all maple trees but Sugar Maple (Acer saccharum), has the highest sugar content and is the one most commonly used for making maple syrup. At Lamb Sugarworks, 90-95% of our maple trees are sugar maple.

TREE TAPPING-THE SUGARBUSH

Stands of trees tapped for maple are referred to as "sugarbushes." Small holes are drilled 2 inches deep into the outer, living portion of the trunk. Each hole is then "tapped" with a small spout that is seated into the tree. Each tap will produce approximately 10-20 gallons of sap per season, and when done properly, healthy maple trees can be tapped each year for their entire life without causing harm to the tree.

SAP ''RUNS'' &

COLLECTION OF RAW SAP

On warm days following freezing nights, sap moves from the spout into a tubing system that transports the sap downhill to collection tanks. Sugarmakers refer to these days as "runs." In a poor production year, there may be as few as 10 separate runs, and in a good year as many as 20. The sap is transported using a truck and tractor from large sap tanks in the woods to the "sugar house" where it is processed into maple syrup. Spouts are removed at the end of the season and new holes drilled each spring.

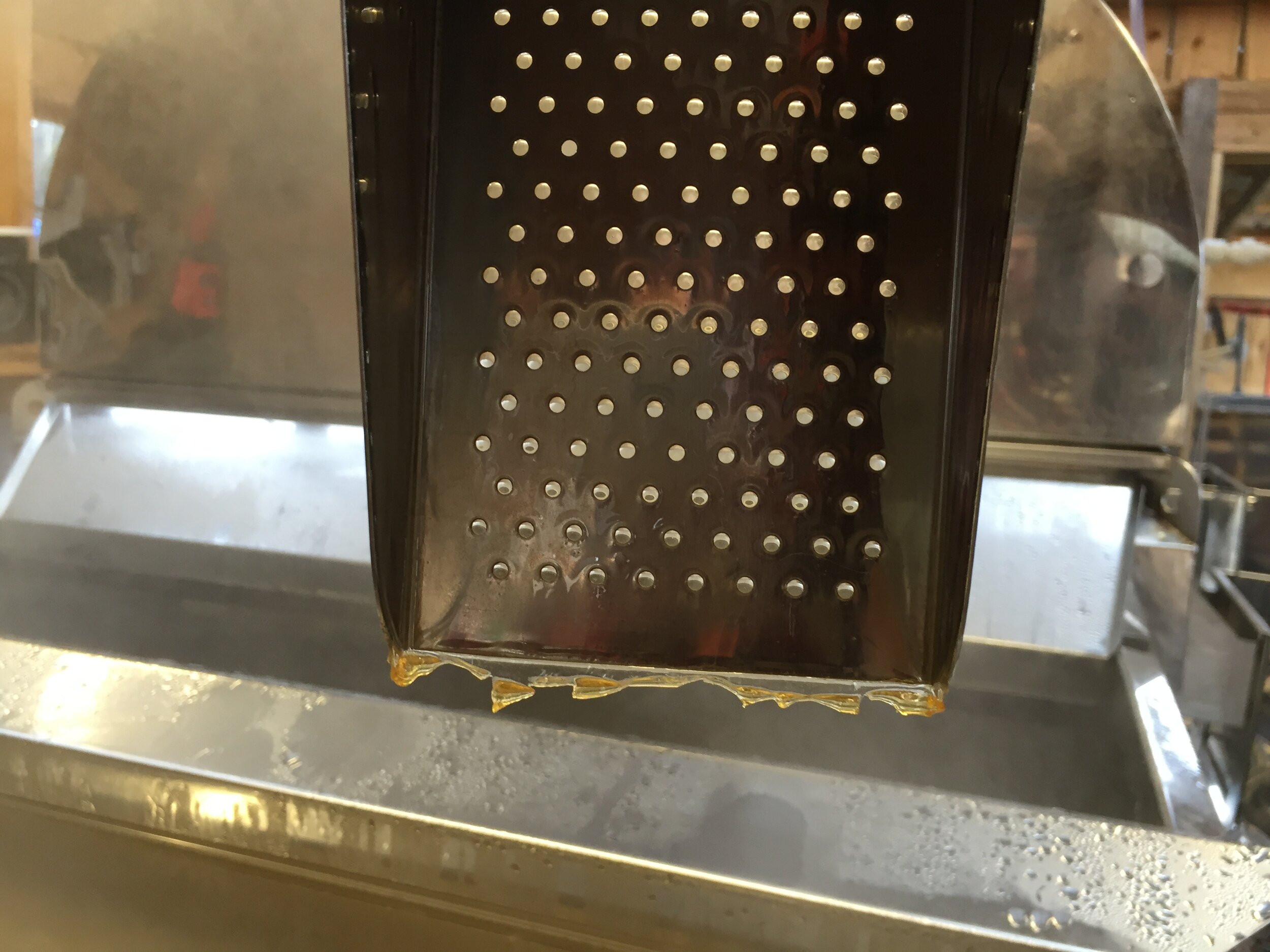

SAP TO SYRUP-THE SUGARHOUSE

Taking raw sap from 2% sugar to syrup at 66% sugar requires boiling the sap to concentrate the sugar. It takes approximately 50 gallons of raw maple sap to make 1 gallon of maple syrup. This process takes place in a large piece of equipment called an Evaporator. There are many different designs but the general goal is the same; to cook the sap as quickly and as efficiently as possible. Our wood-fired evaporator uses the newest and most modern innovations to produce the highest quality syrup.

SYRUP TO TABLE - FILTERING, GRADING, packaging

Cooking the syrup creates natural solids that must be filtered to achieve perfectly clear syrup. After filtering, the syrup is graded by color from lightest to darkest - golden, amber, dark, and very dark. Finally, the syrup is reheated to proper canning temperature to ensure long shelf life and put into glass and plastic containers, or stainless steel barrels for long-term storage.

OUR FAMILY MAPLE FARM -LAMB SUGARWORKS

At Lamb Sugarworks we aim to continue the Vermont tradition of making maple syrup at a small scale with attention to detail. We tap approximately 3500 trees and produce between 1200-1500 gallons of syrup per year, making us a small operation by Vermont standards. We strive for sustainable and conservation-minded maple production. We are proud of our product and hope you will enjoy!

Gallery